Grades | Stainless Steels | X1NiCrMoCu25-20-5, 1.4539, AISI 904L, N08904

EN X1NiCrMoCu25-20-5, 1.4539, AISI 904L, N08904 ( Austenite )

PDF | Word | Print

X1NiCrMoCu25-20-5, 1.4539, AISI 904L, N08904 Application:X1NiCrMoCu25-20-5,1.4539,AISI 904L,N08904 steel is used for the production of systems and equipment for the desalination of water, equipment and machinery in the food, cryogenic and pharmaceutical industries, the production of scrubbers in coal-fired powe

| Elements | Min.(≥) | Max.(≤) | Similar | Remarks |

|---|---|---|---|---|

| C | - | 0.020 | ||

| Si | - | 0.70 | ||

| Mn | - | 2.00 | ||

| P | - | 0.030 | ||

| S | - | 0.010 | ||

| Cr | 19.00 | 21.00 | ||

| Mo | 4.00 | 5.00 | ||

| Ni | 24.00 | 26.00 | ||

| N | - | 0.15 | ||

| Cu | 1.20 | 2.00 |

| Yield Rp0.2 (MPa) |

Tensile Rm (MPa) |

Impact KV (J) |

Elongation A (%) |

Reduction in cross section on fracture Z (%) |

As-Heat-Treated Condition | HBW |

|---|---|---|---|---|---|---|

| 741 (≥) | 649 (≥) | 24 | 23 | 21 | Solution and Aging, Annealing, Ausaging, Q+T,etc | 242 |

| Property | Density kg/dm3 |

Temperature T °C/F |

Specific heat J / kgK |

Thermal conductivity W/mK |

Electric resistance µΩ·cm |

|---|---|---|---|---|---|

| 868 (≥) | 494 (≥) | 31 | 12 | 23 | Solution and Aging, Annealing, Ausaging, Q+T,etc |

| Temp. °C/°F |

Creep strain limit (10000h) (Rp1,0) N/mm2 |

Creep rupture strength (10000h) (Rp1,0) N/mm2 |

- | - | - |

| 928 | 433 | 743 | - | - | - |

| Product type | Products | Dimension | Processes | Deliver Status |

|---|---|---|---|---|

| Plates / Sheets | Plates / Sheets | 0.08-200mm(T)*W*L | Forging, hot rolling and cold rolling | Annealed, Solution and Aging, Q+T, ACID-WASHED, Shot Blasting |

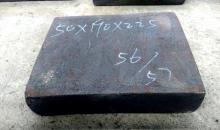

| Steel Bar | Round Bar, Flat Bar, Square Bar | Φ8-1200mm*L | Forging, hot rolling and cold rolling, Cast | Black, Rough Turning, Shot Blasting, |

| Coil / Strip | Steel Coil /Steel Strip | 0.03-16.0x1200mm | Cold-Rolled & Hot-Rolled | Annealed, Solution and Aging, Q+T, ACID-WASHED, Shot Blasting |

| Pipes / Tubes | Seamless Pipes/Tubes, Welded Pipes/Tubes | OD:6-219mm x WT:0.5-20.0mm | Hot extrusion, Cold Drawn, Welded | Annealed, Solution and Aging, Q+T, ACID-WASHED |