Grades | Stainless Steels | Nicrofer 3718 So* - Alloy DS*

DIN Nicrofer 3718 So* - Alloy DS*

PDF | Word | Print

Nicrofer 3718 So* - Alloy DS* Application:Nicrofer 3718 So* - Alloy DS*

| Elements | Min.(≥) | Max.(≤) | Similar | Remarks |

|---|---|---|---|---|

| Ni | 35.0000 | 39.0000 | ||

| Cr | 17.0000 | 19.0000 | ||

| C | 1.9000 | 2.5000 | ||

| Mn | 0.8000 | 1.5000 | ||

| Si | 1.9000 | 2.5000 | ||

| Cu | - | 0.5000 | ||

| Ti | - | 0.2000 | ||

| P | - | 0.0300 | ||

| S | - | 0.0300 |

| Yield Rp0.2 (MPa) |

Tensile Rm (MPa) |

Impact KV (J) |

Elongation A (%) |

Reduction in cross section on fracture Z (%) |

As-Heat-Treated Condition | HBW |

|---|---|---|---|---|---|---|

| 315 (≥) | 772 (≥) | 31 | 32 | 11 | Solution and Aging, Annealing, Ausaging, Q+T,etc | 144 |

| Property | Density kg/dm3 |

Temperature T °C/F |

Specific heat J / kgK |

Thermal conductivity W/mK |

Electric resistance µΩ·cm |

|---|---|---|---|---|---|

| 624 (≥) | 896 (≥) | 11 | 24 | 41 | Solution and Aging, Annealing, Ausaging, Q+T,etc |

| Temp. °C/°F |

Creep strain limit (10000h) (Rp1,0) N/mm2 |

Creep rupture strength (10000h) (Rp1,0) N/mm2 |

- | - | - |

| 367 | 377 | 721 | - | - | - |

| Product type | Products | Dimension | Processes | Deliver Status |

|---|---|---|---|---|

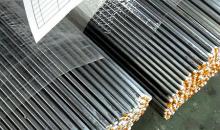

| Plates / Sheets | Plates / Sheets | 0.08-200mm(T)*W*L | Forging, hot rolling and cold rolling | Annealed, Solution and Aging, Q+T, ACID-WASHED, Shot Blasting |

| Steel Bar | Round Bar, Flat Bar, Square Bar | Φ8-1200mm*L | Forging, hot rolling and cold rolling, Cast | Black, Rough Turning, Shot Blasting, |

| Coil / Strip | Steel Coil /Steel Strip | 0.03-16.0x1200mm | Cold-Rolled & Hot-Rolled | Annealed, Solution and Aging, Q+T, ACID-WASHED, Shot Blasting |

| Pipes / Tubes | Seamless Pipes/Tubes, Welded Pipes/Tubes | OD:6-219mm x WT:0.5-20.0mm | Hot extrusion, Cold Drawn, Welded | Annealed, Solution and Aging, Q+T, ACID-WASHED |