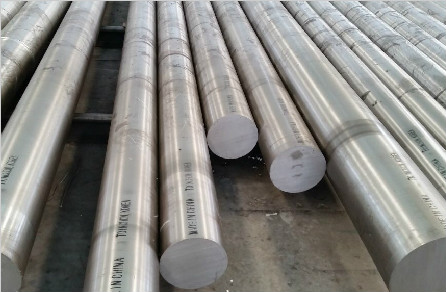

Products | Steels of Blade for Steam Turbine | 1Cr11Ni2W2MoV,961,13Cr11Ni2W2MoV Forged Bars

1Cr11Ni2W2MoV,961,13Cr11Ni2W2MoV Forged Bars

1Cr11Ni2W2MoV Martensitic heat-resistant stainless steel,Keywords: Stainless steel; Grinding; Temperature measurement; Burn mechanism

Delivery Date

Delivery status: Forged 、Q+T 、

Surface: Turned 、

Standard: GBT

Shape: Round, Flat, Square, Hexagon, Plate, Sheet, Other

1Cr11Ni2W2MoV/13Cr11Ni2W2MoV is a kind of heat resistant stainless steel, which is widely used as the material of aeroturbine blades owing to its generally outstanding mechanical property such as excellent toughness, oxidation resistance and corrosion resistance. Since strict requirements of geometric accuracy and surface quality have to be fulfilled, grinding process is always applied as the final finishing of the blades [1].Unfortunately, mechanical properties of high temperature stainless steel 1Cr11Ni2W2MoV make it difficult to grind and may lead to elevated temperatures at the grinding zone and possible grinding burn on surface of the workpiece during grinding with abrasive wheels, which deteriorate the surface quality of the workpiece seriously. Extensive research has been carried out on the surface integrity when grinding high temperature alloy and titanium alloys [2-5], and few studies on grinding burn mechanism of stainless steel was reported. Demands on reducing the grinding costs and increasing grinding efficiency have been posing continuous challenges for the high temperature stainless steel’ grinding technologies. The sol-gel alumina abrasive wheel is a new type of grinding wheel developed in recent years. There have been no profound studies reported on the grinding characteristic of high temperature stainless steel with SG wheels.

chemical composition:

| Product type | Products | Dimension | Processes |

|---|---|---|---|

| Plates / Sheets | Plates / Sheets | 0.08-200mm(T)*W*L | Forging, hot rolling and cold rolling |

| Steel Bar | Round Bar, Flat Bar, Square Bar | Φ8-1200mm*L | Forging, hot rolling and cold rolling, Cast |

| Coil / Strip | Steel Coil /Steel Strip | 0.03-16.0x1200mm | Cold-Rolled & Hot-Rolled |

| Pipes / Tubes | Seamless Pipes/Tubes, Welded Pipes/Tubes | OD:6-219mm x WT:0.5-20.0mm | Hot extrusion, Cold Drawn, Welded |

Enquiry

Categories

Related Grade

Tags